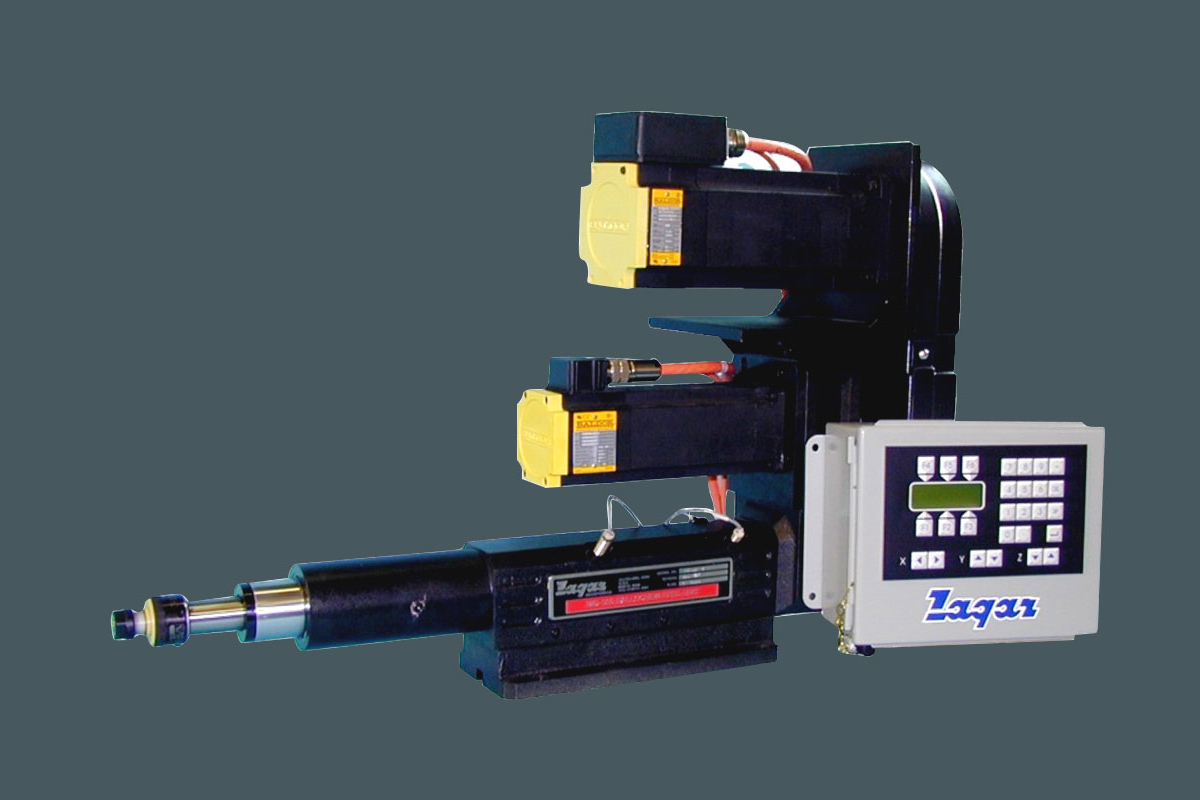

THRUSTER DRILLING UNITS

Solution for drilling requiring both rapid advance and controlled feed

Zagar thruster drilling units are capable of meeting a wide variety of production requirements. Available in four basic thrust sizes, they offer a solution for drilling operations requiring both rapid advance and controlled feed. The same unit features the choice of pneumatic or hydraulic operation, powered by a three-phase, 230/460V motor.

http://www.zagar.com to return to the Zagar Home Page

http://www.youtube.com/watch?v=dtTrMr-uJjo&t=25s for the Zagar Product Overview Video

FEATURES AND BENEFITS

- Greater drilling thrust since our double acting cylinder requires no springs for return

- Efficient power transmission actuated by our involute spline driven spindle

- Rear support bearing on spindle makes for higher radial load capability and reduced spline wear

- Spindle T.I.R. of .0005″

- Adjustable positive stop with .0005″ repeatability for accurate depth control

- Peck feed options for deep hole drilling with small diameters

- Quick speed changes made possible through the interchangeable synchronous belt and pulley kits

- Wide variety of spindle nose options including: Jacob’s taper, drill head tang drive, and Zagar threaded nose for standard Zagar accessories

- Protective guarding for operator safety

- 1, 2 or 3 limit sensor kits for full-back, full-depth, and peck or intermediate positioning control

- Adjustable limit sensor cams